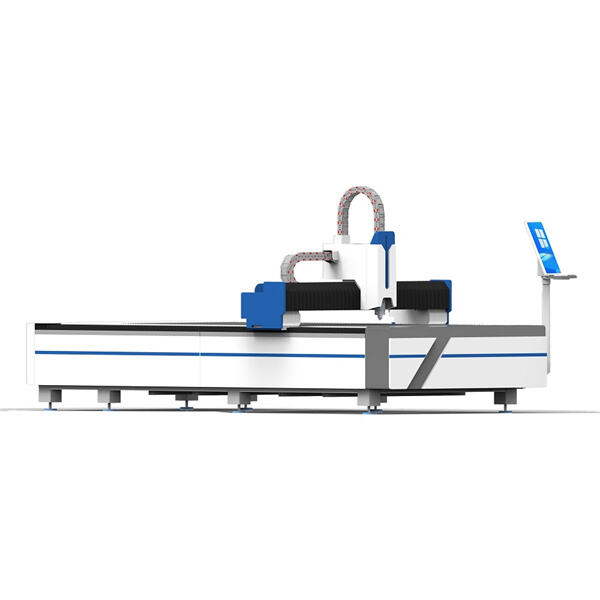

Sheet Metal Laser Cutter: Boost Your Production with Precision Cutting

Do you think you're within the production business and looking to boost your production? sheet metal laser cutter could possibly be the solution you’re happen looking for. We shall speak about what a sheet metal laser cutter is, exactly how it really works, therefore the HUAXIA fiber cutting laser machine, advantages it offers in boosting efficiency.

A sheet metal laser cutter is a machine that actually works from the high-powered laser beam cut through various kinds of sheet metal. The HUAXIA industrial laser cutting machine, process involves melting the material then blowing it away by means of a jet of gas or atmosphere. The result is a precise cut with clean edges that need no further finishing.

Innovation in manufacturing has led to your growth of various machines, with the sheet metal laser cutter being one of them. It offers a few advantages allow it to be the chosen cutting for many manufacturing organizations.

Sheet metal laser cutter provides high accuracy, rendering it perfect for manufacturing parts that need to fit together tightly. The HUAXIA plasma metal cutting machine, machine can no render cuts more than 0.1mm, that means parts can align perfectly, decreasing the dependence on fix or second manufacturing.

Making use of a sheet metal laser cutter, manufacturers increase their productivity. The unit can cut through various types of materials, including galvanized steel aluminum, and stainless metal, with just minimal time and effort. It may also cut through thicker materials, ensuing in quicker production.

Protection is a problem that has been critical production, and sheet metal laser cutter addresses this concern. The HUAXIA industrial laser cutter, machine is made with a security system that prevents injuries due to human error. The security system guarantees the laser beam only works if the machine home is fully closed, preventing any accidents.

Sheet metal laser cutter is easy to make use of, also for newbies. An individual interface is intuitive, with clear instructions on how to operate the product. Furthermore, the HUAXIA cnc laser pipe cutter, unit can store cutting patterns that can be employed for future projects.

Our business give solutions for upkeep, sales and research and development solutions. A lot of the accessories are designed by popular companies. The laser cutting machine produced by Huaxia business is of advanced quality, cutting accuracy is high, the cutting speed is quick The machine has the abilityrun efficiently and it is peaceful. It really is Intelligentfocus, has a full life which are very long, and it will be tailoredfulfill the needs of people.

Huaxia Laser is really a production center which encompasses 20.000 meters that are square well asR and D center of 22,000 meters which is often square . Huaxia Laser is a maker having a factory that encompasses 20.000 square meters andR and D center which is 22,000 yards that are square.Huaxia Laser give 7 products, with 60 designs, and much more than 100 forms of free components. The merchandise are developedmeet certain requirements of most customers. Those goods that can be fiber which are main cutting machines, CNC plasma cutting machines, laser welding machines etc.

Huaxia's considerable business will be the creation of laser equipment and technology. Huaxia Laser is just a ongoing company featuring its staff that definitely a incredibly that the tend which are own be technical. It might supply oem/odm customized plus the ability design machines for distributors and merchants. Huaxia is CE-certified, ISO9000 certified as well as other certifications which can be expert. You might expect 24/7 assistance which are on the internet is technical. Provide 3 years guarantee for Laser Cutting unit.

Our items cover more than 150 nations and regions at domestic and offshore and we also are recruiting representatives around the world. We'll provide people the standard which are better technical service support, welcome consult.

The HUAXIA cnc tube laser cutting machine, standard of this cut produced by a sheet metal laser cutter is exceptional contrasted to cutting that was traditional. The gear produces clean, burr-free cuts that do not require any further finishing. The caliber of the cuts also means that the appropriate parts is of good quality.

Using a HUAXIA cnc laser tube cutting machine, sheet metal laser cutter are not too difficult, provided you've got the necessary equipment training. Follow these steps to make use of a sheet metal laser cutter:

Step 1: Get the sheet metal Prepared

The very action first to prepare the sheet metal you wish to cut. Ensure it are clean, dry, and free from any debris or dirt that could damage these machines.

Step 2: set the equipment up

Next, set up the sheet metal laser cutter. This requires checking the energy provide, setting the main focus, selecting the cutting parameters, and setting up the cutting nozzle.

Step 3: Load the sheet metal

Load the sheet metal onto the equipment bed. Make sure that it is well-positioned, as well as the edges are aligned with all the cutting pattern.

Step 4: Beginning the Cutting

When the sheet metal was protected and loaded, start the cutting. you can do that by pressing the commencement switch on the machine or making use of program to send the cutting pattern to your machine.

Step 5: Check Always the Cut

Following the cutting is complete, check the cut out to make sure it meets the desired requirements. If there are any problems, make the necessary corrections perform the cutting again.

Maintenance and solution are essential regarding the smooth operation of. Manufacturers should make sure that the equipment is well-maintained, and checks which may be regular servicing done. Additionally, quality assurance is important in making sure the HUAXIA cnc laser pipe cutting machine, machine produces parts that meet up with the needed specifications

Copyright © Jinan Huaxia Machinery Equipment Co.,Ltd All Rights Reserved - Privacy Policy