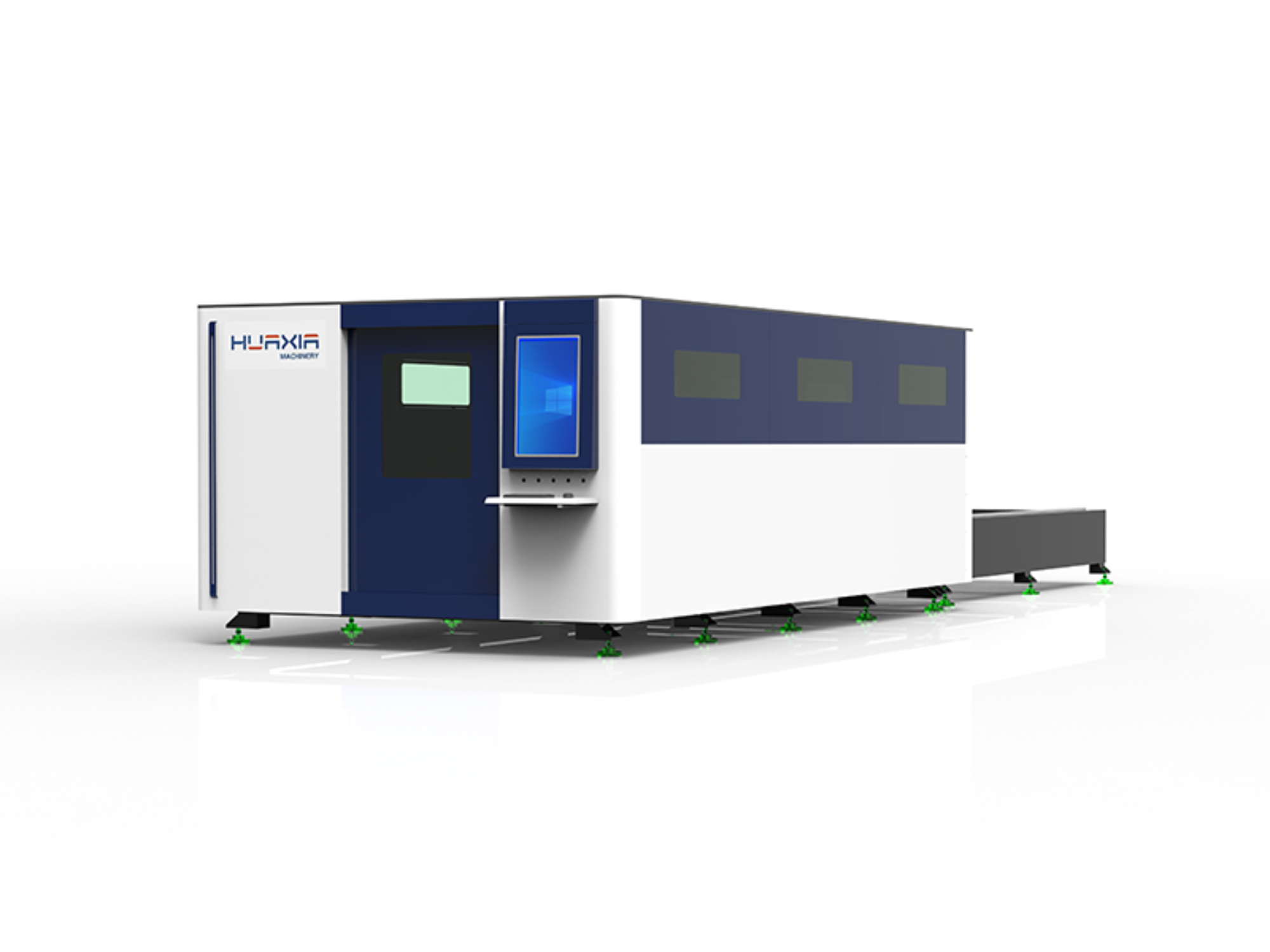

CNC Laser pipe cutting machine is a high tech and powerful machinery which can cut metal pipes that having every single point of the scales in mind. The technology is also being adopted by manufacturers to aid in improving their production processes. This computer-controlled super machine is called a laser and it is designed to cut pipes with the most powerful jet of light. By using this technology manufacturers can save a heck tons of cost and also materialISTIC

Benefits of CNC Laser Pipe Cutter

The good recyclability character of CNC laser pipe cutter is efficient to use the material. It can cut the material in a way that allows for maximum utilization of materials and minimal waste, once programmed. This is crucial as wastage of material not only increases the cost involved in manufacturing, but also has adverse outcomes on environment. In addition to that, the CNC laser pipe cutter is of high quality and performance which can also minimize the errors as well as save a lot more materials. Secondly, in the laser cutting process using high precision; short time on a reduction of not only to save manpower but also reduces power consumption and stage costs. This allows manufactures to make more products out of less raw materials, driving cost-per-unit lower and profit margins higher.

Cutting Pipes Precisely

One of the reasons so many customers have come back to MVC again and again is that our CNC laser pipe cutters are nimble enough, regardless of how intricate or highly detailed a given design may be, even when template notching often leaves unwanted crumbs. The grooves produced by the lasers are very fine and accurate compared with other methods which combined narrowness and heat affected area ensure pipe deformation-free. also IBR metal roofing sheet coil laser pipe machine have the ability to do a much more complex shape and intricate work that many other old fashion cutting equipment cannot finish so each job is perfect accuracy.

The Alternative To Waste:CNC Laser Pipe Cutters

With traditional pipe cutting, however there is room for error and excess resource that gets thrown out due to best practice making it the standard norm for manufacturers waste damaged or over-size materials. You can avoid these by using CNC laser pipe cutters, it also reduces material wastage and saves money as well as the environment.

Changing The Face Of Manufacturing With CNC Laser Pipe Cutting

One such purpose-built solution that facilitates a change in perception is CNC laser pipe cutting, which enables manufacturers to begin their quest for the betterment of materials precision-cutting and utilization. Here is how such a talent, specifically for the right way to cut stuff pays off in cost competitiveness and getting ahead of that whilst at it helping mother nature as well. As it is no-brainer that traditional manner of waste reduction - littering the remaining compounds after production is over, lead to environmental pollution and have outdated years ago due other than these ways being less efficient compared with CNC laser cutting technology generate smaller wastage. This way, the CNC laser pipe cutters trade off between efficiency and precision; it does not waste as much material anymore(which basically saves time in production).

Helping the Environment

This takes away the need to have waste piles, saves space and is environmentally-friendly as well with CNC laser pipe cutters being that type of product. Those manufacturers who opt for this technology can diminish waste so they operate more sustainably, but also enjoy a quick return on investment.

To summarize, CNC laser pipe cutters are a good investment for manufacturers by reducing the steps it would take in fabrication that saves time and money over traditional gas cutting while maintaining adherence to rigorous environmental standards. If businesses have new technology that lets them avoid waste and the depletion of natural resources, they make more $$. This technology opens up ground for far more environmentally friendly industrial production system of today, this right there is the future.