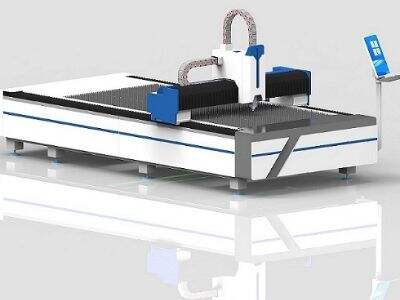

Today we are going to learn some maintenance tips to keep your HUAXIA fibre laser metal cutting machine in good condition. Correct maintenance of your machine is very important for longer duration and to keep it running well. So, let us start to learn on these all.

How to Maintain Your Machine:

It is actually very important to maintain your fibre laser cutting machine. Checking and cleaning the machine regularly can be helpful. This involves inspecting various components of the machine and ensuring that everything is clean and functioning correctly. Checking it regularly will enable you to nip small issues in the bud before they become larger ones.” Be sure to follow the guidelines issued by the manufacturer. It’s because they know the best practices for keeping your machine running great, and following those practices will help you maximize your machine’s life.

Extend Your Machine’s Life:

If you want your HUAXIA fibre laser cutting machine to live a long life, you have to keep it in good shape. That involves such things as oiling the moving parts, looking for wear and tear, and keeping things clean. The oil that you apply to the moving parts allows them to run smoothly and prevents them from getting jammed. As a result of wear and tear, maintenance of cleanliness in the machine is just as vital as cleaning it since dirt is a villain that can bring about quick destruction in the machine components. Thus, remember, if you take care of your machine, your machine takes care of you!

Machine Maintenance: How to Keep Your Machine Purring

Keeping track of the performance of single-mode fiber laser cutting machine is imperative to maintain it in top shape. You're always listening for strange noises, clattering, or error messages that can signal that something is amiss. If you notice a strange sound, that could be a sign that something is not right. Having these problems addressed early on can allow you to avoid bigger issues later on. It's kind of like if you're hearing a strange noise coming from your bike; if you check right away, you won't have a larger issue later.

How to Enhance Your Metal Fabrication Process

Adjusting cnc plasma table is necessary for enhancing metal fabrication. That may mean tweaking such aspects as power and speed and focus. Such settings are very important, as they play a crucial role in maintaining the quality of cuts you make. Shrinking it down implies the cuts may be deeper or more shallow. Change speed to cut faster or slower. Focus makes sure that the laser will cut where you need it to. If you can test the different settings and remember which ones cut best with different materials, it will give you improved quality which in turn makes the metal fabrication process more efficient. It's like making a cake, you sometimes have to change your temperature or your time to make it perfect!

Tips on How to Keep Your Machine Running Efficiently:

Maintaining regular preventive maintenance will have your HUAXIA fiber cutting laser machine running at its optimum. It entails regular cleaning of the machine, inspecting for loose or worn parts, and aligning the laser to make sure it is properly set. Also cleaning the machine regularly will be helpful since dust and dirt can accumulate over time and impact your machines performance. By checking the parts for looseness and wear, you prevent problems before they become a huge issue. This allows you to correct them in time. If you do these on a regular basis, you'll ensure that your machine will continue to function for years to come.

Lastly,plasma cutting mc proper maintenance is the key to maintaining your HUAXIA fibre laser metal cutting machine efficient operation, extending its service life and its operating performance. You can enhance the metal fabrication process by strictly adhering to the manufacturer's guide on maintenance, keeping the machine clean, and closely monitoring how it functions. So, take good care of your machine, and it will (in the long term) assist you in producing better results!