As all the businesses use cutting process there are two hot cutting machines i.e. Plasma Cutting Machines and Laser Cutters. Each of these games has its own unique features to help separate different materials. The aim of this guide is to provide you with knowledge on the key differences between plasma cutting machines and laser cutters. By the end, you will be able to select the right machine for your needs.

Plasma vs Laser

Plasma Cutting:A plasma cutter machine works with a high-speed jet of hot gas called plasma. This jet can slice through all kinds of materials, including metals, plastics, and even wood. Electricity is cranked through gas to create plasma, making a super-hot arc. This arc is extremely hot and burns right through materials (metals) with ease, so cutting through is rapid.

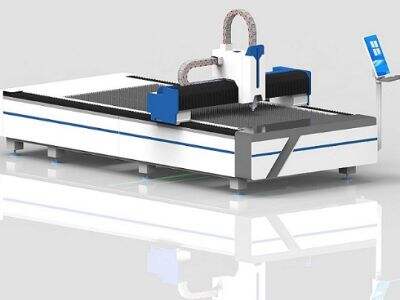

Conversely, laser cutters are a different animal. Using a powerful beam of light known as a laser, they slice through materials. This powerful plasma cutting machine is directed with mirrors that enable precise cuts, creating clean and smooth lines. Laser cutting is generally a default choice for a project where there is a lot of detail involved, such as creating complex designs on metal or engraving well-crafted patterns on wood. This accuracy is also why laser cutters make a favorite choice for many artists and designers.

The Decision: Plasma Vs Laser Cutting

However, when considering plasma cutting machine vs laser cutter, consider what you will be cutting. And get an idea of how precise you need to be. However, plasma cutting machine are often more appropriate when cutting thicker ones, such as temperature metal plates. They are ideal if you need a job done fast as they can slice through even the toughest of materials quickly.

Laser cutters, on the other hand, are the best option when you need to cut thin and smooth materials. If your project needs incredibly finely detailed cuts, such as small designs or fine engravings, a laser cutter is probably the better tool for you. To achieve the best results from your machine, it’s critical to match it with your use case.

Now that you know the benefits of using a cutting machine, you can start to think about which machine is right for you.

Choosing between a plasma cutting machine and a laser cutter depends on what your business requires the most. A plasma cutting machine perhaps is the most efficient option around for your projects if you primarily work with thick, heavy materials demanding fast cutting speeds. They can do the tough work quickly and efficiently.

If you regularly cut materials like thin sheets of metal or wood, and you do a lot of detailed cutting for your projects, then a laser machine cutter is likely a better option. Laser cutters provide precision and detail, making them perfect for projects needing delicate designs.