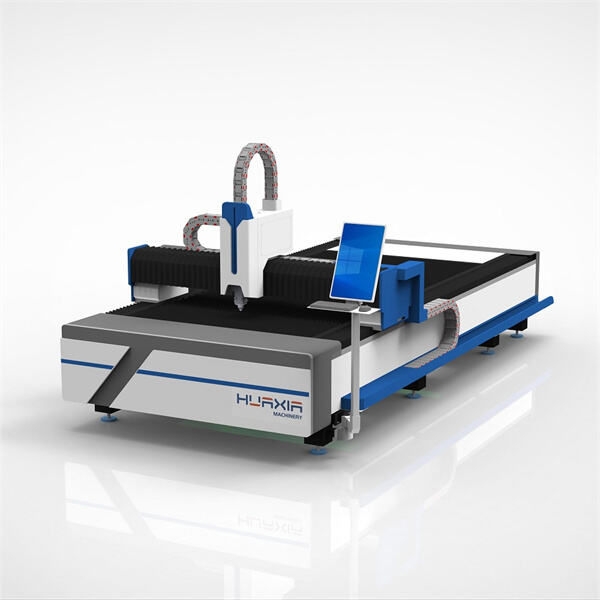

Laser metal machine: Cutting-Edge Technology for Protected and Precise Fabrication

Are you looking for a quicker, more accurate, and safer option to cut metal? Do you wish to build intricate designs small parts or large sheets with ease and reliability? Then you may love to start thinking about using a laser metal machine, a HUAXIA's cutting-edge tool that uses laser beams to melt, vaporize, or shear metals into desired shapes and sizes. We shall explain what a laser metal machine is, what advantages it provides, how it functions, utilizing it, what services and quality you could just expect, and what applications it could support.

One of the main advantages of utilizing a laser metal machine is speed. Compared to traditional methods as sawing, punching, or drilling, a laser machine can cut metal much faster and with higher precision. This means you can save time on manufacturing, reduce spend of content, and increase the production of your business. Moreover, HUAXIA's laser machines can cut metals of different shapes, sizes, and thicknesses, from little screws to spacious plates without changing the cutting tool. This flexibility allows you to definitely respond to different orders for consumer needs with more agility and accuracy.

Another advantage of laser metal machine is innovation. Unlike more tools that rely on physical force to cut metal, a laser machine for metal uses light energy to heat and melt the metal. This technology allows you to definitely achieve smoother edges, cleaner cuts, and more complex shapes than traditional means. You are able to use a laser machine to mark or engrave metals with high precision and clarity, adding value and uniqueness to your products. Furthermore, laser machines can connect to digital design, such as CAD or CAM tools, allowing one to create and customize ease and effectiveness to your designs.

A common concern using a laser metal machine is safety. Laser beams can emit high levels of light and heat that will harm your vision, skin, or lung area if exposed directly and for a right long time. However, HUAXIA's laser machines are designed to reduce these dangers by controlling and enclosing the beams within a protected chamber. This chamber often contains sensors, alarms, and shut-off systems that detect and prevent malfunctions, overheating, or disconnections. Additionally, metal cnc laser machines are monitorable by trained operators who is able to adjust the settings and parameters on the basis of the thickness and type of the metal, the desired cut, and the safety protocols.

To use a laser metal machine, you must know just how it works and exactly how to use it properly. A typical laser machine consists of several parts, a laser generator that produces the beams, a focusing lens directs the beams onto the metal, a gantry that moves the lens across the metal, a cutting table that holds the metal in place, and a control interface that regulates the settings and movements. To cut or mark metal with a HUAXIA's laser machine, you can incorporate one of three modes, pulsed, continuous, or hybrid. The laser emits short bursts of energy that create smaller holes or lines on the metal, suitable for engraving or drilling in pulsed mode. The laser emits a constant flow of energy that melts and vaporizes the metal, suited to cutting or welding in continuous mode. The cnc metal laser switches between pulsed and continuous modes letting you incorporate the precision of engraving with all the speed of cutting in hybrid mode.

You need to make sure you obtain a reliable, durable, and supportive tool that may last for ages and meet your expectations when you invest in a HUAXIA's laser metal machine. Consequently, you ought to choose a reputable and experienced manufacturer or supplier that offers high-quality products and services, such as warranty, maintenance, training, and technical support. A good laser machine should have high beam, energy, and accuracy, suitable for cutting or marking various metals including steel, aluminum, brass, copper, and titanium. It should also need an intuitive control panel, and a safety reliable system. Moreover, a good supplier provide after-sales assistance, such as troubleshooting, upgrades, or replacements, in instance of any issues or problems with the laser machine metal.

We now have representatives in 150 nations world wide Our items are available across over 150 nations. We will offer users utilizing the quality help which are technical. Please please ask questions.

Our organization combines study and development, manufacturing, sales and maintenance solutions. The equipment we use consists of popular companies. Huaxia laser devices that are cutting quality. They will have excellent cutting accuracy, large cutting speeds, also low sound. Its Intelligentfunction, having a life which are very long, and it may be tailoredgenerally meet because of the needs of individuals.

Huaxia's significant company is the manufacturing of laser gear and technology. Huaxia Laser has actually its staff that could be individual that technical give oem and solutions which are often odm which are modifying which can be in times tailor the device for vendors, resellers and customers that are different. Huaxia company is CE, ISO9000 along with other official certification which are official is professional. Tech assistance is online all hours being full the full time. Provide three years guarantee for Laser Cutting device.

Huaxia Laser is simply a manufacturing center that covers 20.000 yards that are square along withcenter which are r and D of square yards . Huaxia Laser is actually a maker with a manufacturing center that covers 20.000 meters that are squareR and D facility that addresses 222,000 yards that are square.Huaxia Laser has 7 item series including significantly more than 60 designs also over 100 types of free components and accessories that fulfill the requirements of customers in complete terms. The main items include fiber laser gear that definitely a CNC which are cutting plasma machines and laser welding devices, amongst others.

Copyright © Jinan Huaxia Machinery Equipment Co.,Ltd All Rights Reserved - Privacy Policy