Top steel sheet cutting device.

Introduction

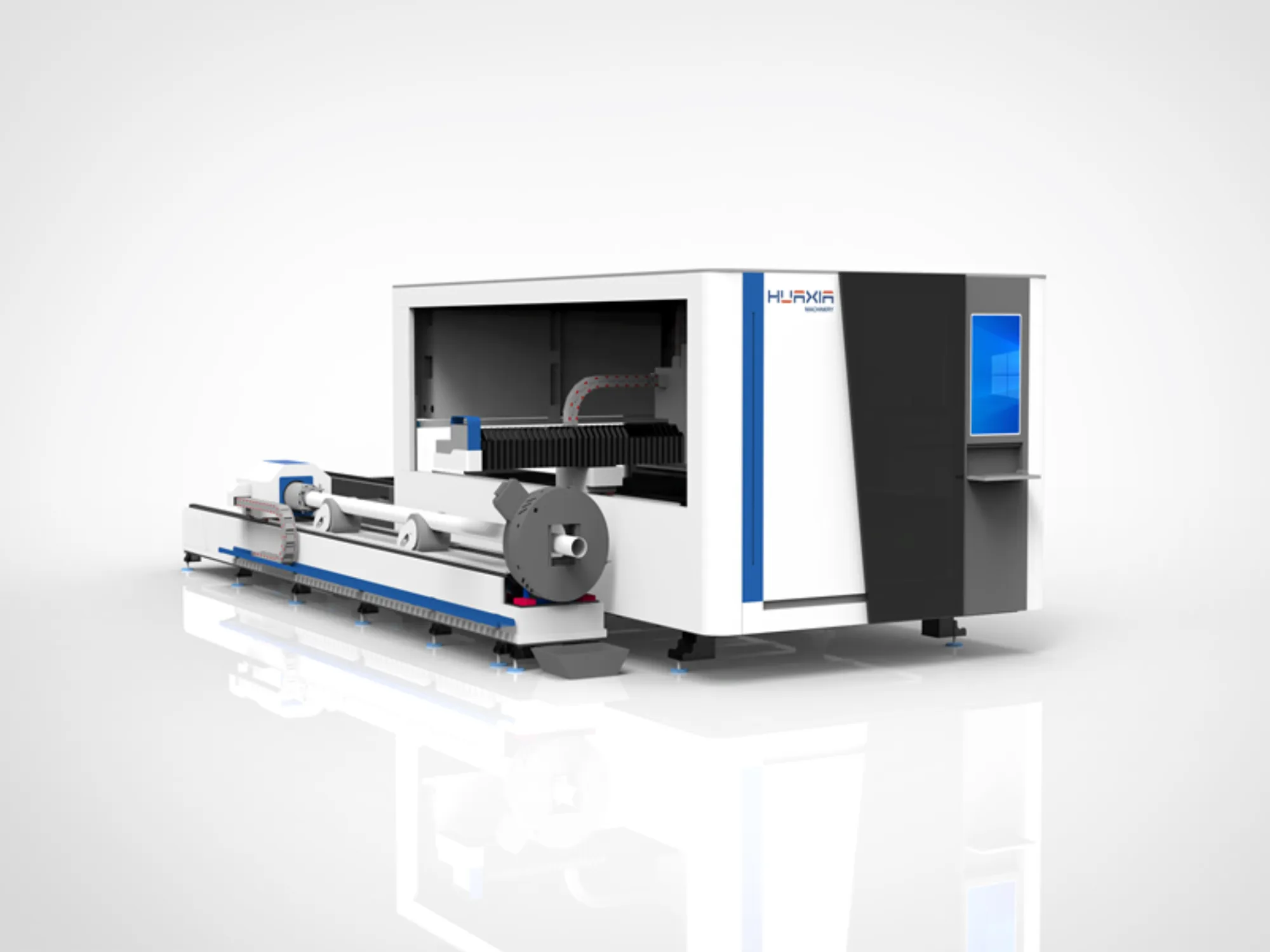

Do you wish to find out about the very best 10 steel sheet cutting device? Metal sheet devices which can be cutting the devices which can be regularly cut steel sheets. These devices have large number of benefits that produce HUAXIA ideal for numerous companies which are various. They're revolutionary devices that increase security and offer quality outcomes, we'll explore advantages, innovation, security, usage, utilizing, solution, quality, and application of steel sheet devices being cutting.

Benefits

Metal sheet devices which can be cutting countless benefits. They could be always cut steel sheets of various thicknesses, sizes, and forms. Also, they are extremely exact, meaning that the cutting is quite accurate. Also, extremely fast and certainly will cut lots which big of in a brief timeframe. An additional benefit is the fact that they're user friendly, meaning anybody can utilize them.

Innovation

Metal sheet devices being cutting really revolutionary devices that utilize today's technology to cut steel sheets. The steel sheet cutting machine normally use computer-aided design and production that's computer-aided create exact cuts which are really accurate. Additionally, they utilize lasers, waterjets, or plasma to slice the steel sheets. This technology increases security and saves time.

Security

Security can be an consideration which essential utilizing steel sheet cutting devices. The sheet metal laser cutter devices were created with security features that protect an individual from damage. As an example, the devices have actually shielded that protect the consumer from cutting procedure. There is also security sensors that detect whenever one thing is incorrect and straight away stop the device. The security features make metal sheet devices which can be cutting and minimize the possibility of damage.

Usage

Steel sheet cutting devices are utilized in lots of companies which can be various. They've been found in a which automotive cut steel sheets for vehicle systems and components. Also utilized in the construction industry to cut steel sheets for structures and bridges. They're utilized in the aerospace industry to cut steel sheets for airplanes and spacecraft.

Utilizing

Making use of steel sheet devices which are cutting simple. First, the steel sheet is positioned on device's sleep. Next, the equipment is switched on, while the cutting procedure starts. The cutting procedure can by hand be managed or with a computer. The sheet is taken off the device following the cutting procedure.

Service

Metal sheet devices which can be cutting routine upkeep to help keep them running well. The devices have to frequently be washed to eliminate any debris or dirt which could restrict the cutting procedure. Additionally, they have to be examined frequently to make certain that every one of the right components work precisely. Regular upkeep means that the devices are operating precisely and quality that's creating.

Quality

Metal sheet devices being cutting top-quality cuts which can be really exact and accurate. The devices utilize modern tools to generate cuts which are neat and have finish which smooth. This leads to an item which top-quality matches the client's objectives.

Metal sheet devices which are cutting found in numerous companies, even as we talked about early in the day. They have been accustomed cut steel sheets for several applications being various such as for example aerospace, automotive, construction, plus much more. The devices can cut steel sheets of various thicknesses, sizes, and forms, making them devices which can be versatile may be used for different applications.

Have you been interested in the very best 10 steel sheet cutting device? Steel sheet cutting devices can be a component which crucial numerous companies that depend on the complete and top-quality cutting of steel sheets. They feature stainless steel laser cutter numerous benefits like accuracy, durability, and effectiveness. Alongside these benefits, additionally they bring security and innovation towards dining table, making them a must-have for most companies, we shall look into advantages, innovation, security, usage, utilizing, solution, quality, and application of this steel sheet devices which are cutting.

Benefits

Steel sheet cutting devices are designed for cutting steel sheets of varied thicknesses, sizes, and forms by having a level that's a lot of. They have been understood for his or her rate and effectiveness in processing an amount which significant of very quickly. Aside from this, they're also user-friendly, helping to make them more straightforward to run.

Innovation

Steel sheet cutting devices utilize advanced level technologies such as for instance computer-aided designing, computer-aided production, and laser, waterjets, or plasma cutting. These devices leverage automation and robotics that help to improve the accuracy of cuts and minimize expenses which can be functional. In addition, they're incorporated with high-end security features particularly shields and sensors that ensure the procedure which safe of devices.

Security

Among the critical factors whenever steel which making use of cutting devices is security. Security features such as for example shields can protect the operator even though the device is being used. Features including sensors and alarms can identify any breakdown and prevent the equipment immediately. The operators will also be taught to abide by security protocols and use gear that's protective decrease the threat of damage.

Usage

Steel sheet cutting devices end up in several companies which can be diverse. They're beneficial in a which automotive fashion vehicle components and figures, plus in the construction industry generate walls, roofs, and bridges. In addition, they are likely involved which critical the aerospace industry the make of airplane elements and components and spacecrafts.

Utilizing

The steel sheet is first positioned on the sleep of this device to employ a steel sheet cutting device. After creating the equipment, operators begin the cutting procedure, that may differ predicated on manual or control which computerized. Following the sheet cutting procedure is complete, the sheet is taken off the equipment. Operators must make sure they clean the equipment frequently and continue maintaining it to effortlessly keep it operating.

Service

Metal sheet devices which can be cutting regular upkeep to retain functionality while increasing durability. An operator should perform upkeep that's regular including cleansing, greasing, and assessment of device to ensure all components are operating properly.

Quality

Metal sheet devices which are cutting popular because of their accuracy, precision, and effectiveness in processing steel sheets. The devices make clean cuts that create a item that's completed satisfies vendors' specs and clients' objectives.

Application

Metal sheet devices which can be cutting possibly useful to lots of companies for instance the automotive, construction, and aerospace sectors. They find application in a selection of areas, like the generating of automobile components, the fashioning of walls, roofs, bridges, and aircraft elements.