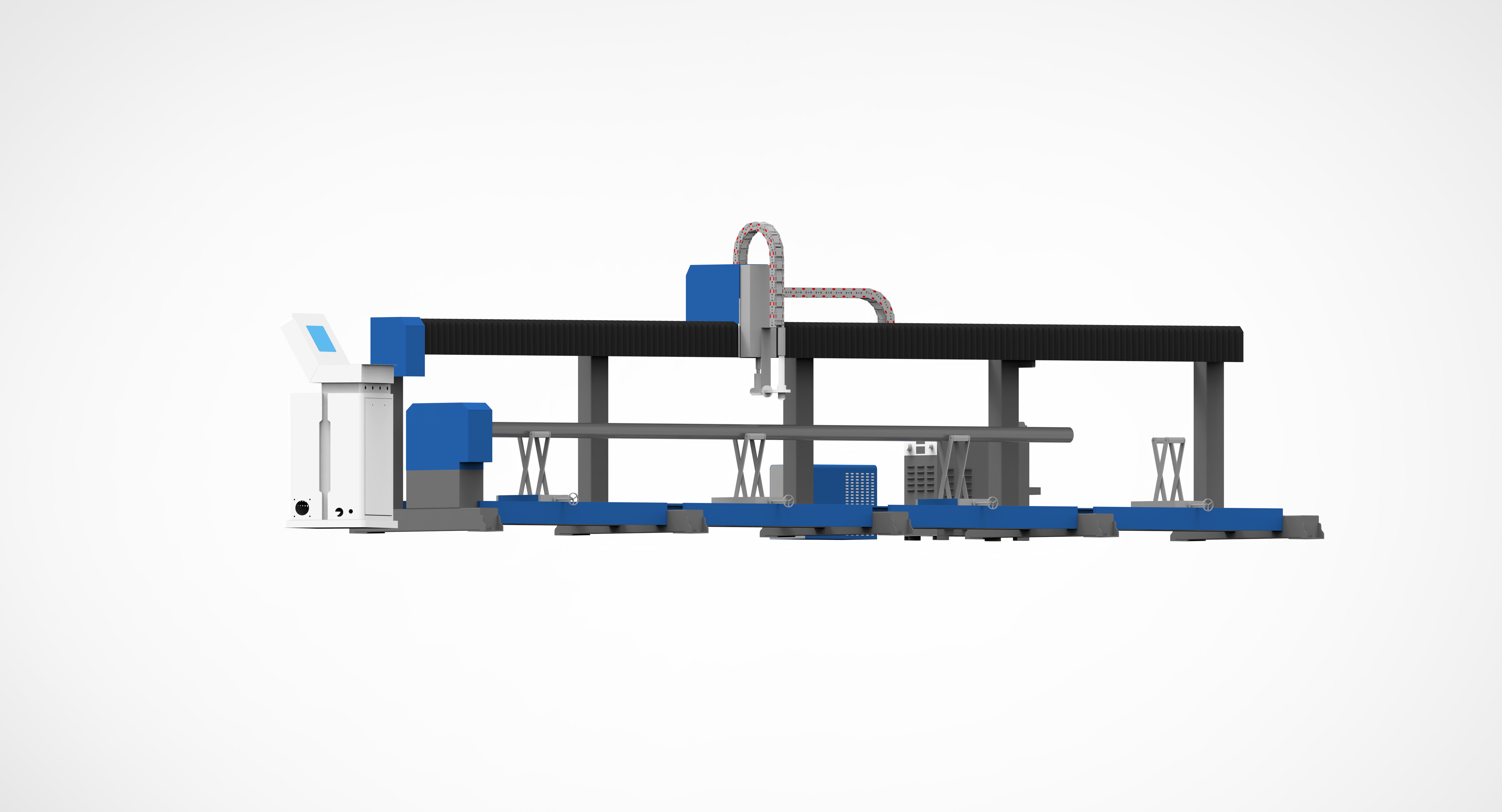

Jinan HUAXIA High Speed single Round Pipe Plasma Cutters CNC Plasma Cutting Machine with TubeMaster software

- PRODUCT DETAILS

- RELATED PRODUCTS

- Inquiry

PRODUCT DETAILS

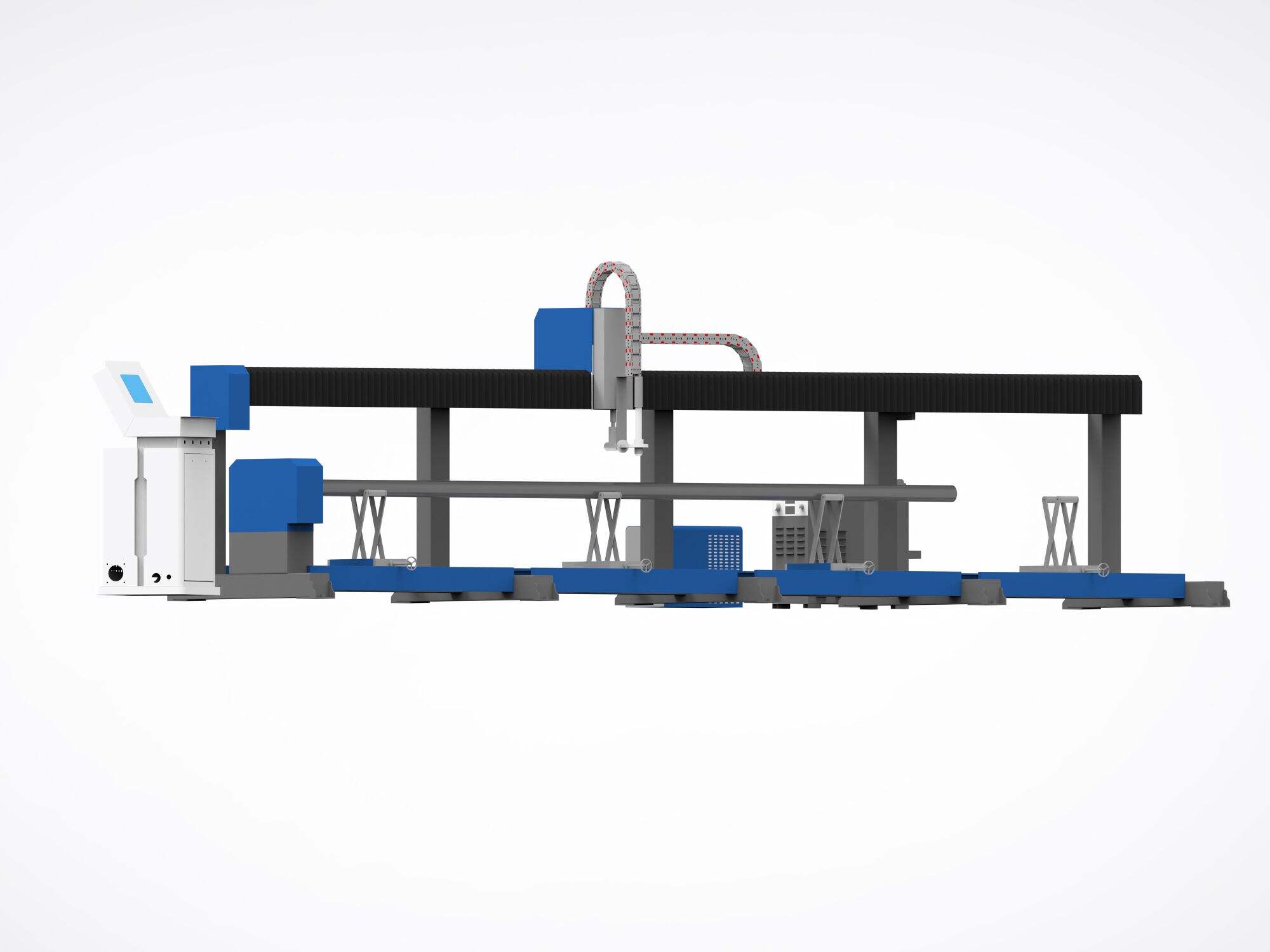

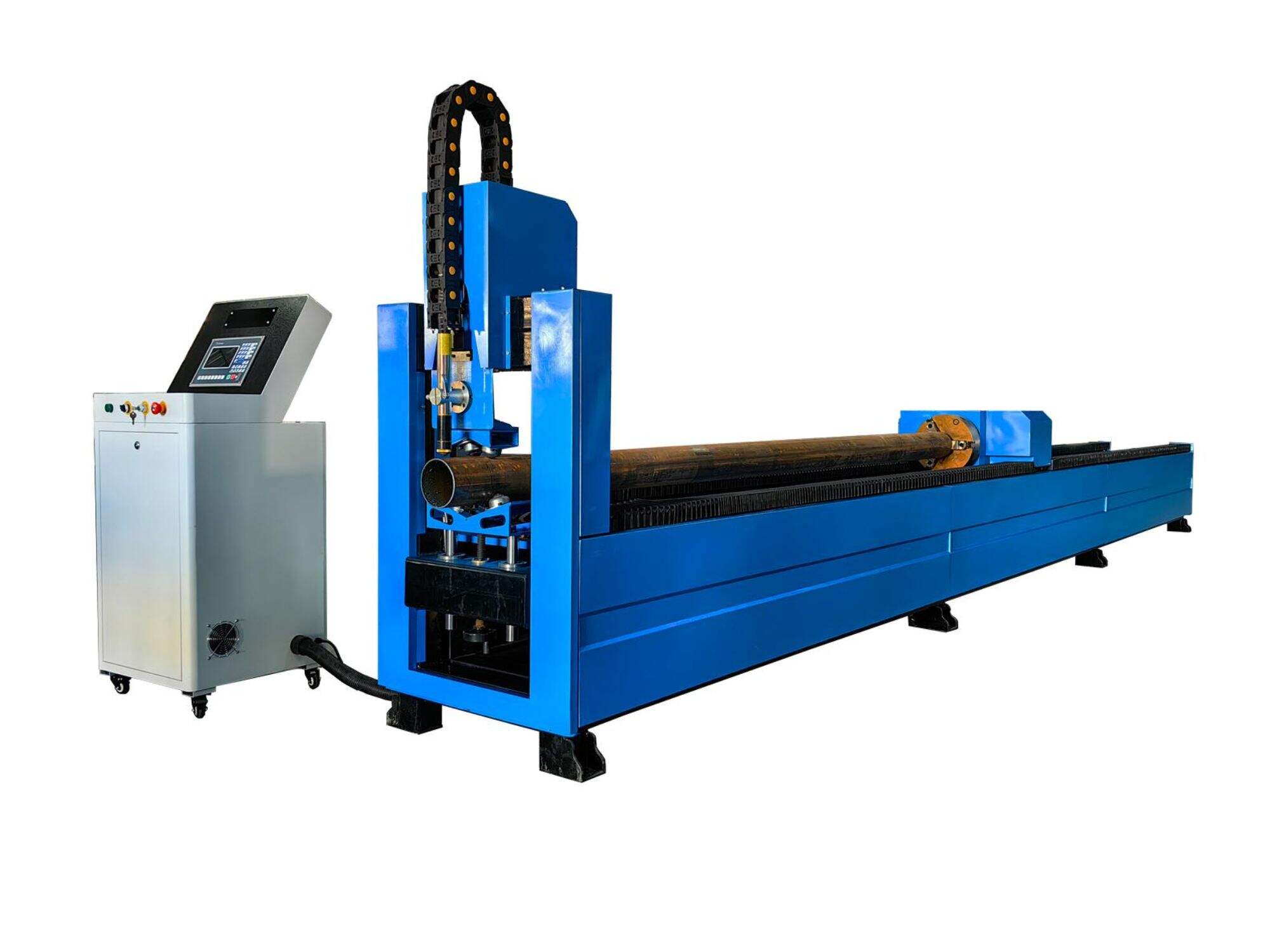

The Jinan HUAXIA Higher Rate solitary Rounded Pipeline Plasma Cutters CNC Plasma Reducing Device along with TubeMaster software application is truly a essential product towards any type of company that needs accurate effective reducing of rounded pipes. This device guarantees towards provide excellent efficiency that cannot be matched through just around any type of rival offered on the market together with its own progressed features advanced innovation.

The HUAXIA brand name was popular for the exceptional high top premium services and products, along with the Jinan HUAXIA Higher Rate solitary Rounded Pipeline Plasma Cutters CNC Plasma Reducing Device along with TubeMaster software application has no exemption in contrast towards that. This device is developed towards concentrate on the distinct reducing of rounded pipelines, it happens geared up along with a more powerful CNC plasma reducing device that guarantees precise cleanse reduces each time.

The Higher Rate solitary Rounded Pipeline Plasma Cutters CNC Plasma Reducing Device along with TubeMaster software application follow particularly customized towards help with programs easy command for the CNC plasma reducing treatment. Unlike various other software application, Tube Master is extremely easy to use as well as user-friendly, therefore creating it simple for drivers of any type of amount of proficiency to put it towards utilize great.

While utilizing the Jinan HUAXIA Higher Rate solitary Rounded Pipeline Plasma Cutters CNC Plasma Reducing Device along with Tube Master software application, you can easily anticipate precision optimal is reducing price, significance that you will discover a method towards create much a lot extra products in much less opportunity. The reducing price of device is lightning-fast, which conserves improves efficiency opportunity.

Another incredible include of High-Speed solitary Rounded Pipeline Plasma Cutters CNC Plasma Reducing Device along with TubeMaster software application it is truly appropriate for lots of products, coming from steel towards light weight aluminum, iron, and copper. This device has you dealt with whether you are utilizing slim or even thick pipes that are rounded.

Details and advantages:

|

Model

|

HXP-6000

|

|||

|

Cutting range(mm)

|

6000*220mm/6000*350mm

|

|||

|

Maximum cutting thickness

|

Depending on the power of the plasma supply

|

|||

|

Cutting speed

|

100m/min

|

|||

|

Machine power

|

35KW

|

|||

|

Input power supply

|

380V

|

|||

Automatic arc pressure function: Through the arc pressure sensor, in the whole process of cutting. The height of the torch is kept constant, even if the workpiece is not at normal height. It can still be cut, and the constant height of the cutting torch ensures a high level of cutting quality.